Sunflower Seed Preparation and Oil Extraction - ScienceDirect

- Type: sunflower oil plant

- Usage/Application: sunflower

- Voltage: 220 V

- Weight: 390 kg

- Post-warranty service: Online technical support

- Oil type: Palm oil

- Main components: motor, pressure vessel, pump, bearing, motor, gearbox, others

- Country: lusaka

Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons (FAO, 2013). The deoiled meal composition

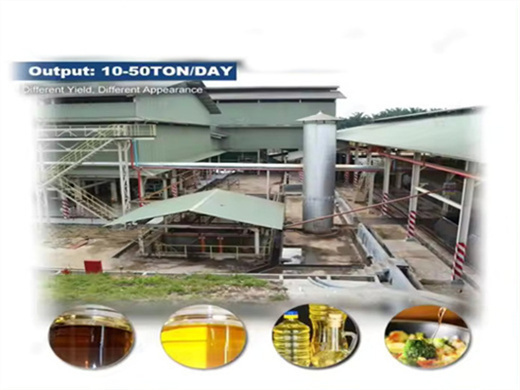

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil processing machine

- Production capacity: 93%

- Voltage: 380V/Others

- Warranty: 1 Year

- Weight: 520kgs

- Dimension (L*W*H): 2000X620X770mm

The most suitable temperature for the growth of sunflower seed is 20 – 27°C with abundant water. There are several varieties of seeds available consisting of 36% of Oil to 40% oil-based on cultivated area soil condition and species of the seed. The oil extracted from sunflower seeds either by Screw Press or by Solvent Extraction Process.

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

Sunflower Oil Extraction Process, Methods – A Full Guide

- Usage: sunflower oil

- Production capacity: 400-500 kg/h

- Voltage: 380 V

- Main components: motor, pump

- Weight: 1100 KG, 360kg

- Dimension (L*W*H): 1850 *1700*1700mm

Sunflower seed oil is obtained from the seeds within the brown hub in the center of the sunflower plant. Sunflower oil is light in taste and gives more Vitamin E than any other vegetable oil. Sunflower oil is mainly composed of less-stable polyunsaturated and monounsaturated fatty acids, it can be most susceptible to degradation by heat, air

The purpose of pressing is to extract sunflower seed oil by mechanical pressing while providing pressing cakes for extraction plant. Main processes include: Seed Cleaning , Stone Removing& Weighing, Peeling, Flaking, Cooking, Pressing, Oil Residue Separation, Sunflower Seed Cake Extraction

A Review of Methods Used for Seed Oil Extraction - ResearchGate

- Type: cooking oil extraction machine

- Production capacity: 10tpd

- Dimension (L*W*H): 2300mm*1000mm*1300mm

- Voltage: 380V

- Weight : 950KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, cold and hot pressed oil processing

extraction o f essential oil from caraway seeds, in Conf. Rec. 2003 App lication of Power Ultrasound in Ph ysical and Chemic al Processing, Becanson, lagos, pp. 349-

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Raw Material: sunflower

- Voltage: 380V/50HZ

- Dimension (L*W*H):1700*1100*1600mm

- Power (W):2.1KW

- Weight: 20000KG

- Certification:CE ISO

However, the fiber content in sunflower byproducts is inversely proportional to the protein content [64], varying concerning husks' presence. Sunflower byproduct obtained from hulled seeds has a

This study investigates variation of physicochemical characteristics between sunflower seed oil extracted by cold pressing (CP) and Soxhlet extraction (SE) methods. SE exhibited higher sunflower seed oil yield (42.5%) as compared with the CP (21.4%).